Modeling

Beamline & Shop Automation

Process

Pacific Coast Iron is a LEED compliant steel contractor that utilizes Lean scheduling principles and practices. Throughout the estimating, detailing, fabrication and installation process we take pride in not only managing our responsibilities, but improving the experience with minimum cost and maximum value; delivering on a customers needs.

Estimating

With more than 125 years of combined hands-on experience in steel fabrication and erection, we take pride in delivering comprehensive, competitively priced, and accountable project proposals. Our goal is to provide the right number—not necessarily the lowest—and to collaborate with your team to identify cost-effective alternatives that keep projects within budget. We excel in fixed-price, design-build, and multi-prime project delivery frameworks.

Detailing

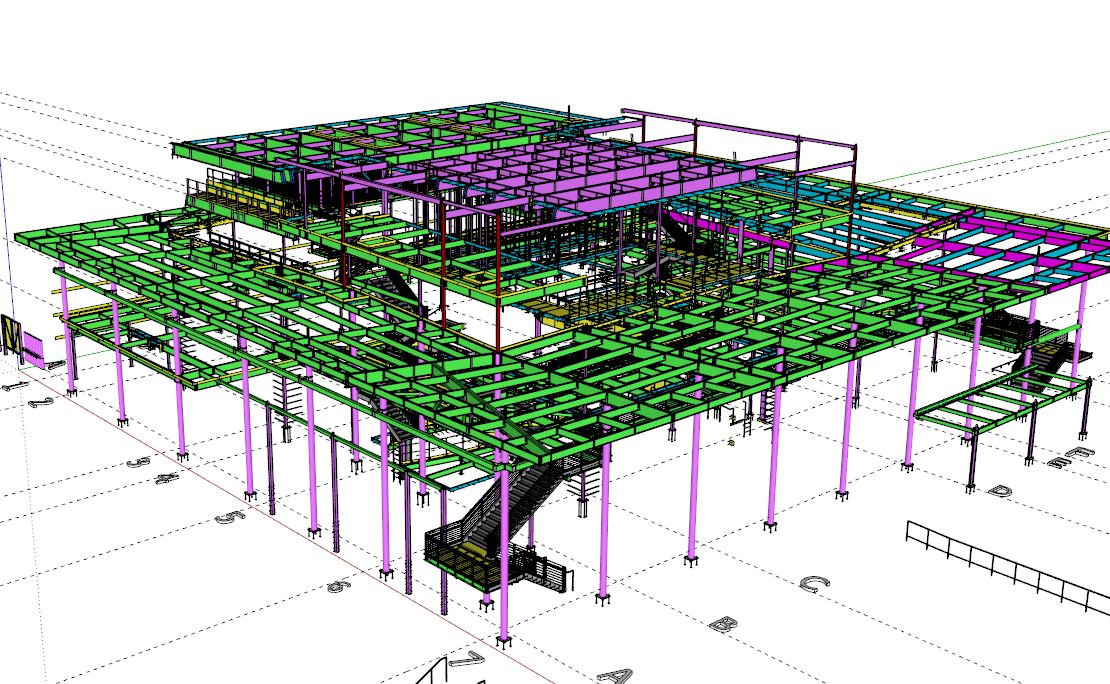

Through a rigorous vetting process, we have established strong partnerships with multiple detailing firms both in the U.S. and internationally. Utilizing advanced 3D modeling platforms such as Tekla Structures, Advance Steel, StruCAD, and other state-of-the-art software, we have the capacity to manage a wide range of complex projects with precision and efficiency.

With the addition of Mr. Peter Sanchez in 2019—formerly the owner of Eiffel Steel Detailing Services—we expanded our in-house detailing capabilities, providing additional resources to identify and correct potential detailing issues well before fabrication begins. We are proud to combine this enhanced capability with the automated beamline we installed in 2018, allowing us to deliver exceptionally high-quality, accurately detailed, and timely fabricated steel for your projects.

Fabrication

Our 77,500 sq. ft. fabrication facility is equipped with six overhead cranes and precision-calibrated, computerized equipment capable of handling projects of all sizes. Our certified journeyman welders consistently deliver the highest standards of quality and craftsmanship.

In 2018, we expanded our production capabilities with the addition of an Ocean Machinery Liberator Automated Coping Machine, an Integrated Voortman Beam Saw & V630 Drill line and a Peddinghaus FDB 1500 Plate Processing Machine. Machinery Avenger 2 Drill Line. Together, these advanced systems enhance our capacity, accuracy, and overall efficiency—enabling us to deliver superior-quality fabricated steel with speed and precision.

Installation

Over the years, we have forged lasting relationships with multiple steel erectors throughout Southern California. We work closely with our erection partners to plan every aspect of each project — including detailing, sequencing, loading, erection aids, and coordination with other subcontractors.

Our project managers collaborate directly with your on-site teams to ensure that steel erection is performed safely, efficiently, and in full coordination with other trades. Potential issues are anticipated well in advance, and when challenges do arise, they are addressed quickly and professionally to keep the project on track.